描述

The system serves for the parallel test of the color and intensity of self-luminescent objects – particularly FPD & LED – in the visible area of light. With this modular system, it is possible to test 1 up to 961 FPD & LED in parallel. The measuring procedure is based on measurements in comparison to reference products by means of user-specific parameters.

Disturbances through environment light are automatically compensated. Color and intensity of the test objects can be separately parameterised and evaluated. The measurement time for e.g. 31 objects amounts to app. 300 ms.

Main characteristics of the system:

– Parallel test of FPD & LED for their color and intensity

– Detection of erroneous mounting of series resistors

– True Color Cromaticity x,y,Y

– Variable interfaces I/O and serial

– spectrum Resolution to 2nm

– Resolution of 12 bit

– Dynamic >90 db

– 6-12 amplification levels

– Wavelengths 450 – 750nm

– Temperature compensation within the range from 20-55 degrees °C

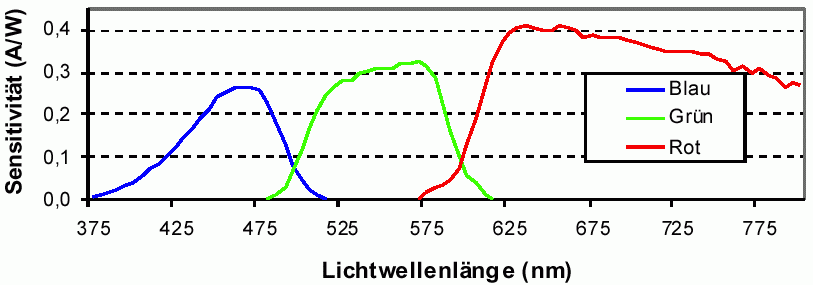

The figure 1 shows the spectral distribution curve of the integrated three-sector color sensor. The sensor values are enhanced in a way, that a color outcome is generated in independence from the intensity.

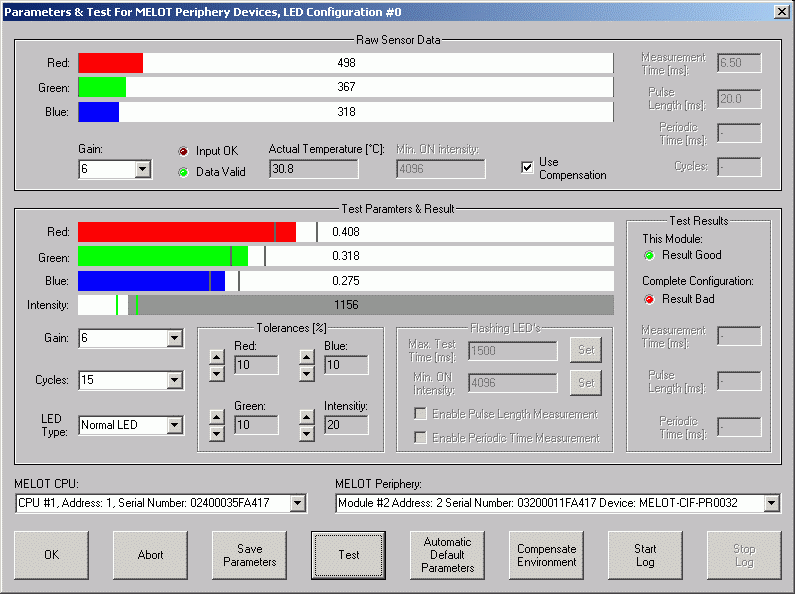

The scope of delivery includes a comfortable intuitive software tool for the commissioning, parameterisation as well as the statistical evaluation of test results. It allows for the parameterisation of „n“ different products. In the software tool, the input states of the ongoing product’s signals are continuously displayed. An automatic “basic settings” function facilitates the determination of the parameters. The result is further optimised through the statistical evaluation of larger measurement series. By means of the tool, test and compensation cycles can be actuated and data can be imported or exported.

Additionally, a detaiFPD & LED description of the serial interface as well as a DLL are available, clarifying all commands that enable the user to record the mere sensor values and process them with his own software. This is often necessary if the user requires a greater product traceability.

The system provides two different interfaces with the first interface being optimised for the connection via digital I/Os. Therefore, a handshake protocol is utilised which permits a stable communication but, simultaneously, the monitoring of the module’s as well as the connection lines’ function. The digital interface generates a separated good/bad outcome. The second interface is accomplished as a serial RS232 interface. We also offer RS422 models that can be connected to a bus. This interface is at least needed for the commissioning using the software tool. The module can, moreover, be exclusively operated via the serial interface, allowing the user e.g. to process the sensor values with his own software. Both interfaces can be used in parallel.